Rosita's Art from the Heart blog

overzicht

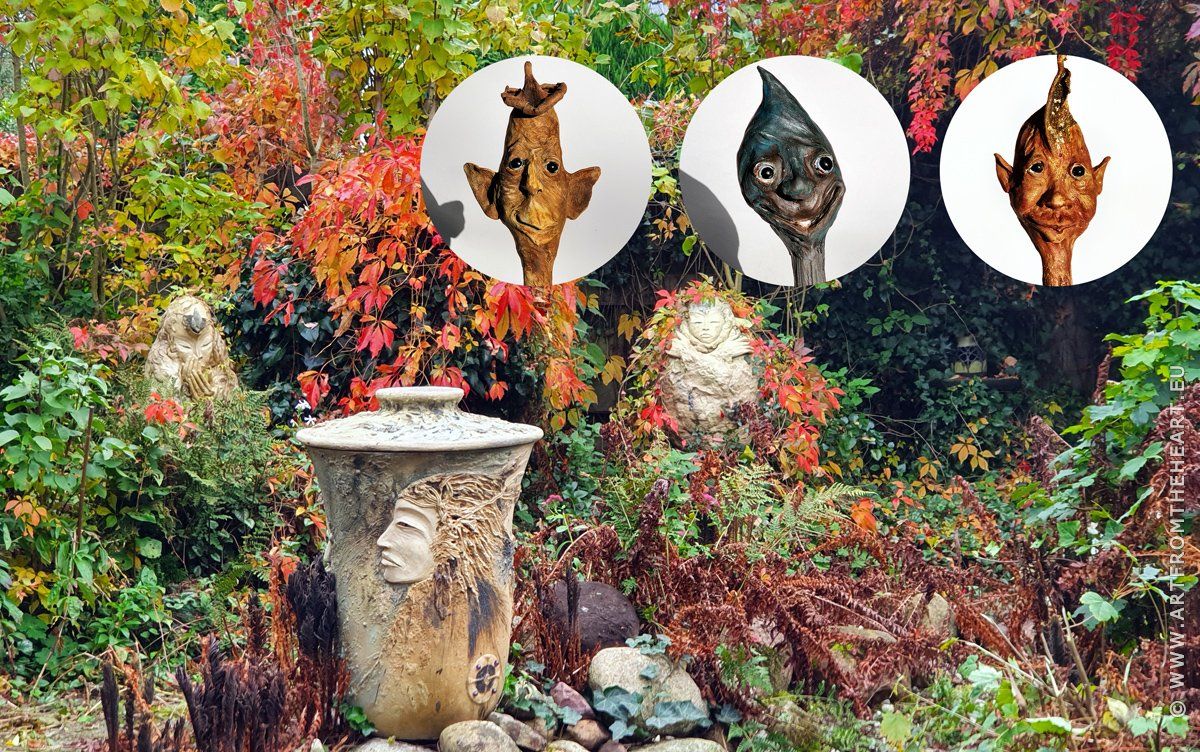

Atelier Art from the Heart

sinds 1994

Roswinkel, Drenthe

Rosita maakt alleen nog vrij werk en neemt dus geen nieuwe opdrachten meer aan. Atelierbezoek voor aankoop na afspraak

© 2024

ArtfromtheHeart.eu All rights reserved

No part to be copied or used elsewhere

without our strict permission, thank you

Art from the Heart <3 is een project van

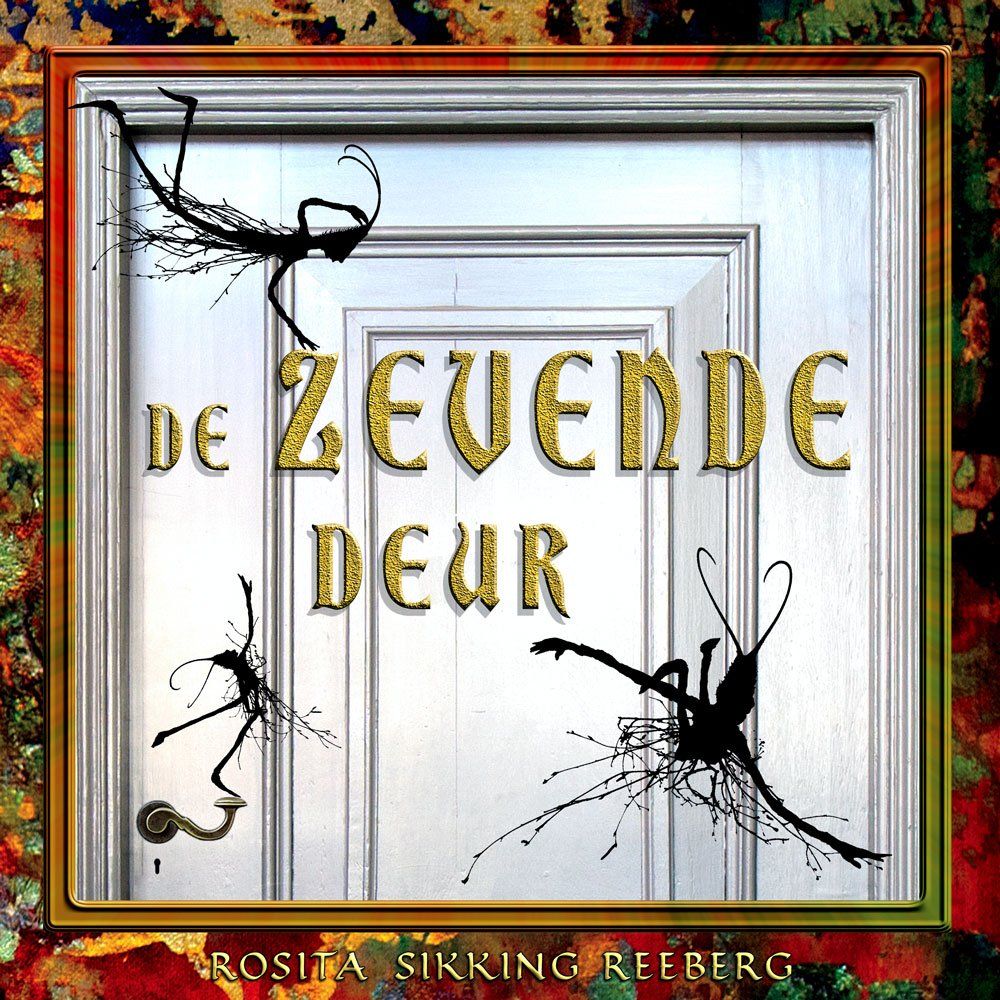

Frans Sikking en Rosita Sikking Reeberg